Justway Manufacturing Services Review

I’m a MAKER. They used to call us nerds, and then geeks. I personally own a CNC machine, four 3D printers, 5 lasers, a vinyl sign machine and some of the best tools money can buy. Before I go to the store or head to the internet to buy something I stop and ask myself, “Can I make this myself”. A lot of times I can. Even sometimes when I can it isn’t practical for me to do so or I find that I can’t make it out of a preferred material. Or I have reached the limits of my machines. This is where Justway comes in.

Justway is a manufacturing service that can make ALMOST ANYTHING. They specialize in:

- CNC Machining and Milling

- Sheet Metal Fabrication

- 3D Printing

- Injection Molding

- Urethane Casting

Their services are ideal for almost anyone. And their services really excel in a few different areas. If you dreamed up a great idea and you needed to build a prototype but have no manufacturing ability then Justway is a perfect choice for you.

Additionally, if you needed to mass produce something then Justway services would be ideal for you. From an individual standpoint let’s say that you wanted to print a cool 3D widget but you didn’t own a 3D printer.

Here’s another great example. Let’s say you DO HAVE a 3D printer but your print quality for a certain item is not to your satisfaction and it would look superior in a Resin or Nylon build up. Justway really shines here.

My Personal Example

Whoops!

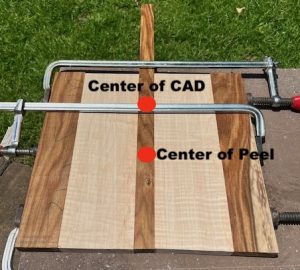

I’m a woodworker and I made a fancy pizza peel for myself. When I put it on the CNC machine I put the center machining mark in the middle of the rectangular peel area instead of the actual center of the CAD drawing.

Whoops!

What happened was that my nice long handle got cut off during the CNC process.

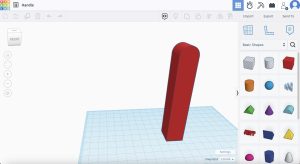

Brilliant guy that I am I decided to make a rubberized handle on my 3D printer which I did. I designed it in TinkerCAD.

It didn’t look good and the FLEX material looked very unprofessional compared to the expensive exotic wood I used for the peel. I want to emphasize here that the pic below is a part that I made.

This is where a service like Justway can really excel. I was able to upload my STL CAD file up to their service and have it manufactured out of Resin material. I’ll show the results later after we talk about the process.

Background Stuff That Needs Mentioned

First of all I need to say that Justway contacted John’s Tech Blog and offered their services in exchange for a blog entry. I was provided with an account up to $100 in manufacturing services. In exchange I was to blog about their service.

At no time has Justway compensated me additionally or applied any pressure for a positive review. In fact now is good time to say that I will never accept to review any item if pressure is applied to me. If the reviewed item is good, that’s what you’ll read about. If it is bad, you’ll read that too.

When someone is confident enough in their product to not attempt to influence your review then you know that they TRUST THEMSELVES.

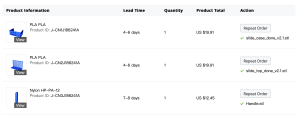

With all this in mind I did my very best to NOT spend their $100 and started with inexpensive items. Just because they offered it doesn’t mean I should take everything I can get.

The Justway Process

I decided that first off I would order something that I could make myself. This was meant for comparison. I decided to get a Raspberry Pi case printed.

Economic Feasibility

I’d be remiss if I didn’t mention this. You can buy Raspberry Pi cases pretty cheap. Cheaper than you can get them manufactured.

The caveat here is that I had a specialty case printed. A Raspberry Pi + a HiFiBerry Digital to Audio Converter case which came in two pieces. You can’t really buy those. I provided two STL files and the cost to print each half was just less than $20 each. Two pieces plus shipping came to around $60 total.

Again I want to reiterate that if your item is a commonly manufactured widget you’ll want to look at the price before utilizing the service.

However, if you are prototyping an item such as this SIXTY DOLLARS IS A BARGAIN.

If you have an expensive or sentimental item that needs to be repaired……SIXTY DOLLARS IS A BARGAIN.

If you are buying one to inspect for a sample before making a mass production order then SIXTY DOLLARS IS A BARGAIN.

Back To The Process

Before you can use the service you’ll need a CAD drawing of some sort. Example types of files are:

- .STEP

- .STL

- .STP

- .X_T

- .IGES

- .IGS

- .SLDPRT

- .OBJ

- .DWG

- .DXF

The internet is full of free downloadable files that you can upload to get manufactured. Or if you have some CAD skills you can create your own. For example I designed my pizza peel handle myself in TinkerCAD.

Not very complicated at all.

Once you upload your item by clicking on the “Get Instant Quote” button on their website you’ll then need to select the material, color, and any other manufacturing parameters dependent upon what material you select.

Process Review

Once this is submitted your item will go into a Review process where it is analyzed by an Engineer to ensure it can be manufactured to exacting specifications.

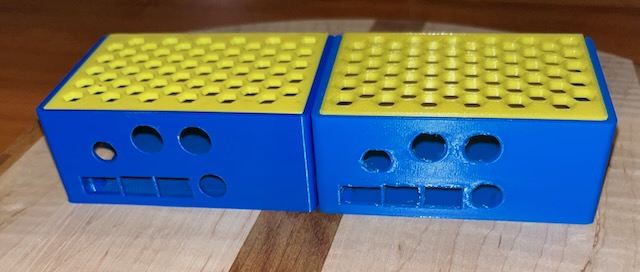

This is a good time to note that the STL file I submitted for the Raspberry Pi case had some thin walls and problematic areas. I didn’t design the file but just downloaded it from the internet. Justway contacted me and let me know their Engineers noted these areas and asked if I wanted to proceed.

I think the point I am making here is that you don’t just upload some questionable drawing and they make it whether it is good or not. They reviewed it, found an area of concern, and they contacted me. By my estimation, this is how it should be.

My impression was that they were trying to achieve the best possible quality and they even made a couple of recommendations regarding material selection. Yes, this takes some time but don’t you want the best possible quality?

Once The Drawing Is Approved

Once the engineer AND THE CUSTOMER are happy it heads to manufacturing. You’ll be given a notification of estimated lead time.

Then they make it, and ship it to you. My order was just received and I am impressed with the turnaround time and the quality. On my Pi case they sent me the original that had some deficiencies and then they sent the finished product. I don’t believe they would normally send the first attempt to a customer but because we are collaborating they were being completely transparent with me and sent it to me for comparative purposes. The item on the left is the finished product.

Raspberry Pi Case Comparison (click pic to enlarge)

Again, I’ll state that I own four 3D printers and I could have printed this Pi case myself. Their quality is as good or better than what I can do myself. And as someone who has 3D printed a lot of stuff I can tell you that to improve the print quality from the 1st printed item to the finished item means someone there knows what they are doing and did some tweaking.

So, color me impressed.

Pizza Peel Handle

My pizza peel handle, while a simplistic design came out AMAZING. I ordered it in black nylon. My internal dimensions were 15mm x 15mm with 2mm walls. My measurements confirmed that they nailed my specs to exacting standards. The peel handle fit PERFECTLY.

Peel Handle (click pics to enlarge)

My mistake of cutting the handle too short was corrected by the folks at Justway. The black nylon part has a far better fit and finish than anything I can produce here.

Wrap Up

I’m really impressed with the Justway production services I received and can highly recommend their company. We as a society are so quick to throw things away that are broken. Why not have that broken part remanufactured and keep your item out of the landfill?

Also the world is full of brilliant DIY engineers who make fantastic upgrades to our household devices and then they share them to Open Source platforms. Why not simply download that file and have Justway make it for you?

And what if you are that brilliant DIY engineer who doesn’t have a resin printer or you can’t make that sheet metal enclosure? Draw it, and send it to Justway to prototype for you. Or if you need a production run.

I see no downside with this service at all and I just don’t think services like this get the exposure they should. We just throw it in the trash and buy a new one. There are people out there that can make just about anything. Justway is one of those places.

John’s Tech Blog Highly Recommends Justway. Check them out.

“I am highly satisfied with this machined product. Firstly, the dimensional accuracy is exceptional, perfectly matching the design specifications without any deviations. Secondly, the surface quality is excellent, with a smooth finish and no visible flaws or indentations. The material selection is also appropriate, offering the desired strength and rigidity to meet our requirements. The machining time is efficient, contributing to our production schedule. Furthermore, the consistency in quality among the multiple products we ordered demonstrates effective production control and quality management. Most importantly, these products are reliable and durable, performing flawlessly in our application environment over an extended period. Overall, the quality and performance of this machined product are outstanding, and we are highly satisfied with its performance.

Great article, thanks for the recommendation!