BEST LABEL MAKER

In my last post I determined that there were several requirements that I needed a label printer to meet. We are looking for the best label maker there is. Essentially any printer that I want to own will have:

- Ability to do labels up to 1 inch in width.

- Ability to connect to software for designing labels.

- Ability to do QR codes.

- Rechargeable Battery

- AC adapter included

- Ability to do print and cut heat shrink tube for wiring.

I had more items on the last list but these are must have’s for me. To get these features though means you’ll pay more. A label maker that just spits out simple labels can he had for as cheap as $20 or so. To get what I have listed above requires an investment of over $250 and even a bit more.

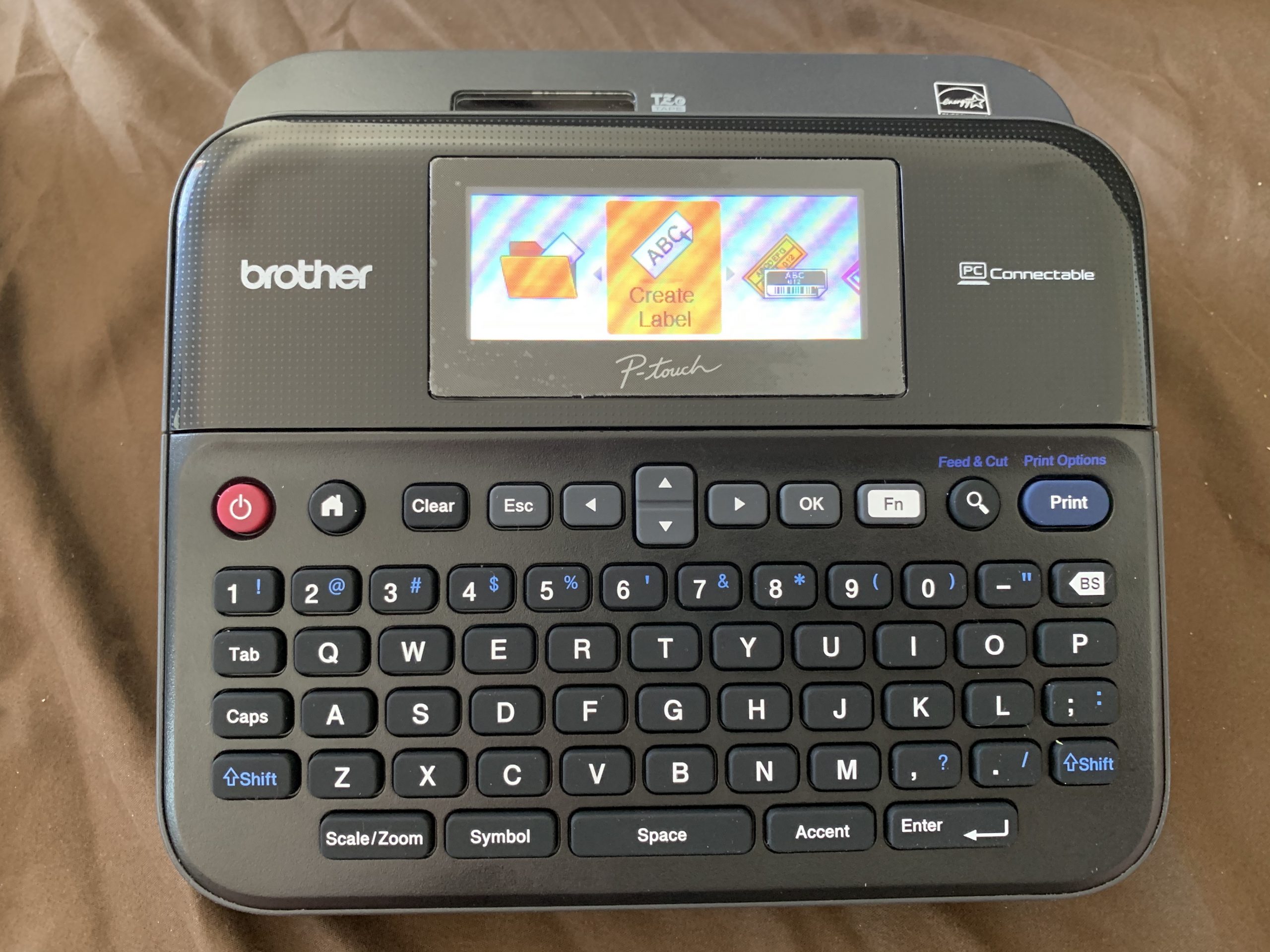

Brother PT-D600

If you are willing to drop the requirement for a rechargeable battery, everything else on my list is available in the Brother PT-D600 making it a heck of a bargain at about $79.99 most places. To be honest with the first label maker I owned, a K-Sun 2001XLB I never put batteries in it. I would just plug it into the wall and use it. Yeah, it was a little more hassle but batteries are expensive, recharging takes time, and a label maker is something I may not use for long periods of time and I might get some battery leakage or corrosion.

To get the items in my list in a Dymo printer costs about $250 by jumping into the XTL line of printers. Dymo has some models that come SO CLOSE that are a lot cheaper. It is so disappointing that there seems to be a $150 gap or so to get a couple extra features. So many printers exclude heat shrink, hooking to a PC, and 1 inch wide tapes. Those printers are mostly less than $100.

The Dymo Rhino models (4200 @ $60, and the 5200 @ $125, for the printers only, not the kits) are close but the maximum size label you can use is 3/4 inch wide, nor do they hook to software. But they do heat shrink tubing. Close but no cigar.

The Dymo LabelManager 420P at the really decent price of less than $100 hooks to software but isn’t compatible with heat shrink tubing. Also it only cuts 3/4 inch maximum width labels too. 3/4 inch is way fine for most tasks but just not big enough to cut the mustard with large tasks. However if you are a casual home user and will never need to label wires then the LabelManager 420P may be EXACTLY WHAT YOU WANT.

“It is so disappointing that there seems to be a $150 gap or so to get a couple extra features. “

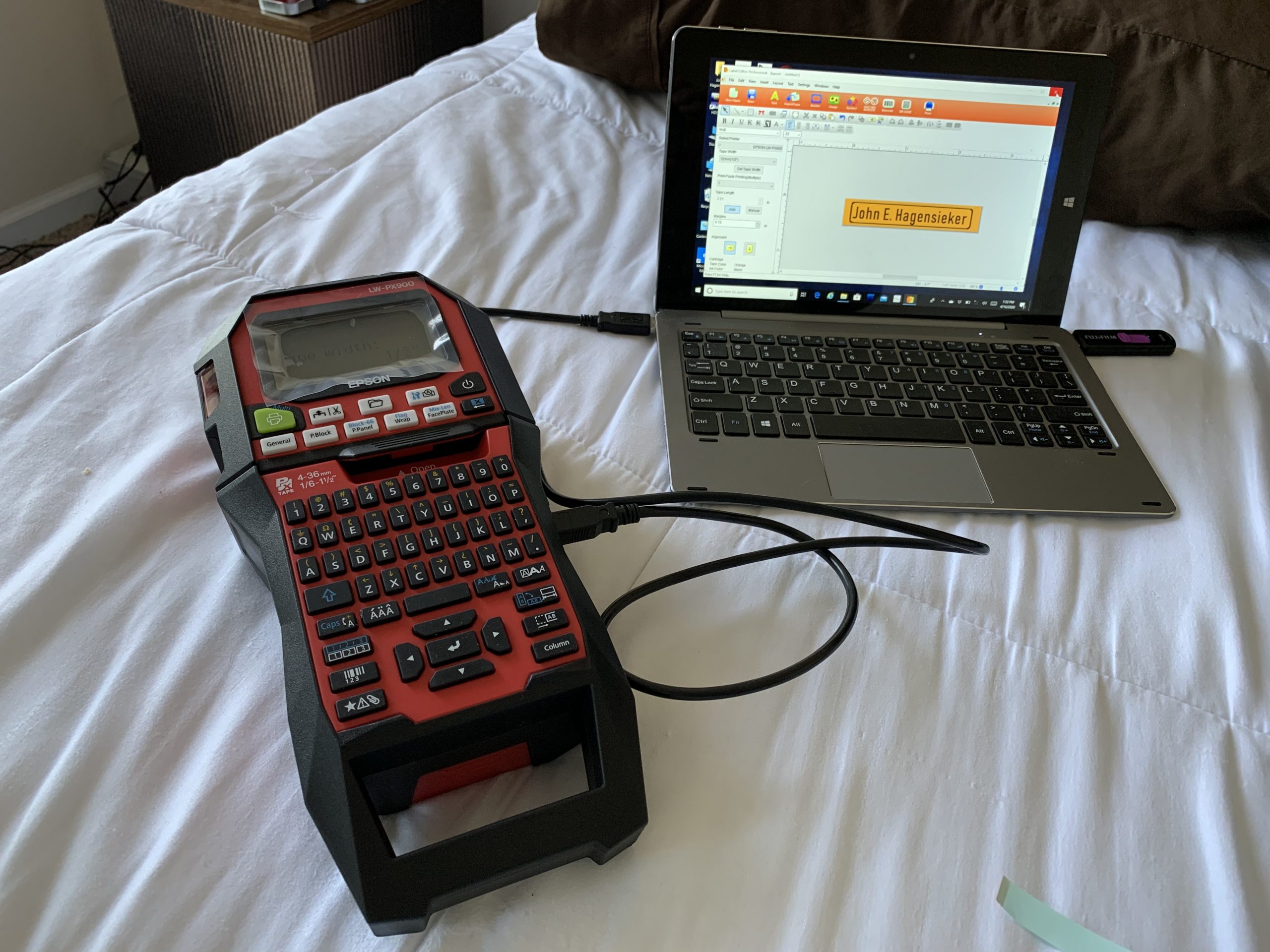

And just because a label maker has the ability to do heat shrink tubing, that doesn’t mean you may get many refill options. Epson printers have various colors of shrink tubing such as black, white, yellow, and red. As an electronics guy, having red and black for positive and negative puts a fine professional touch on some projects. With Brother and Dymo you get White shrink tube and that’s it I believe. Adequate, yes, but it just doesn’t go all the way. Why buy an expensive label maker if it falls short of what you want to accomplish? As I write this the Epson LW-PX900 is still the baddest label maker on the planet. Bar none.

Epson LW-PX900 Label Maker

But you’ll pay dearly for it at around $290 just for the label maker. More for the kit with battery and carrying case and AC adapter.

Now for the Dymo offerings. To meet the requirements of my list you have got to get a Dymo XTL series printer. They have the 300 and the 500. I opted for a 300 and I bought it from LabelCity. Less than $200 for the printer and $235 for the kit. Also that $235 price is WAY lower than anyone else at the moment. I was a little hesitant at first but I placed the order and in a couple minutes I got an email from the company saying one of the tapes I bought was not compatible with the XTL 300 but was with the XTL 500, and did I know that and what did I want to do?

EXCELLENT CUSTOMER SERVICE ALERT!!!! Great price, and helpful! Do not hesitate to buy from LabelCity.com

But here again with the XTL printers from Dymo we have a condition where a few extra features that I deem necessary pushes you into the $250 range and that is without consumables. Label makers are only fun and useful if you have a variety of materials.

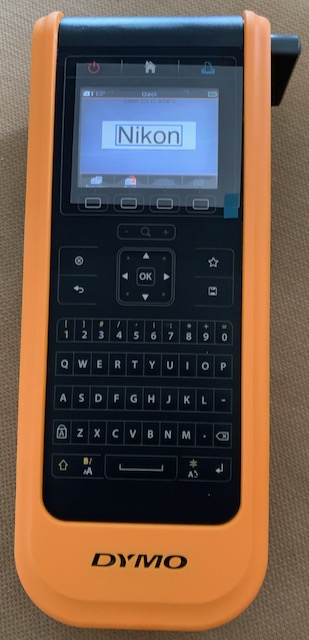

Stock Photo of Dymo XTL 300 Kit

So here’s a stock photo of the XTL 300 kit. Mine should be coming in the mail sometime today.

I’m a sucker for a carrying case. Why buy an expensive tool and then just toss it in a closet or toolbox where it is bound to get all beat and scratched up?

Again, AC adapters and rechargeable batteries are a MUST for label makers. While the Dymo XTL 300 has a rechargeable Lithium (LiPo) battery ONLY, most of the competitors devices can also take 6 AA batteries or more. They just won’t last all that long. Also while I use rechargeable batteries in almost everything and I own several chargers I have yet to own a charger that can charge 6 AA batteries at once. You can charge 4 batteries. That’s it. So if your batteries die you’ll have to go through 2 charge cycles before you can use your device. Not acceptable. You may read a lot of label maker reviews but nobody ever points that out. Here at John’s Tech Blog we live in the real world and are practical users of tech. I call it the way I see it.

In my Epson LW-PX900 it will either use a Lithium rechargeable battery OR 6 AA cells.

Lithium or AA Batteries Choice in Epson LW-PX900

If you are on the job site and the Lithium batteries die at least you can have the option of slapping some store bought batteries in the machine to get you through. Enough of that. Back to the XTL 300. Just unboxed mine!

Dymo XTL 300

It’s pretty cool! Here are my first, first impressions without messing with it too much.

I like the size, the shape, the weight. Screen is bright and it seems fairly intuitive to navigate around (so far). Changing cartridges is pretty easy.

The battery door removal to install the battery and then installing the door back was a pain in the you know what but hopefully that is a one shot deal. It has a lithium battery which (fingers crossed) I shouldn’t ever have to change.

I’m not sure if I’m a fan of the manual tape cutter though. My other two favorite, higher end label makers have an automatic cutter.

It’s not the end of the world nor a deal breaker but I just find it unusual. Top feed of the tape is odd too but in many respects it seems like where it should feed out and it would likely have less propensity to go flying out after printing if you have manual control of the cutting process, I suppose.

Hard for me to say until I give it a proper shake down.

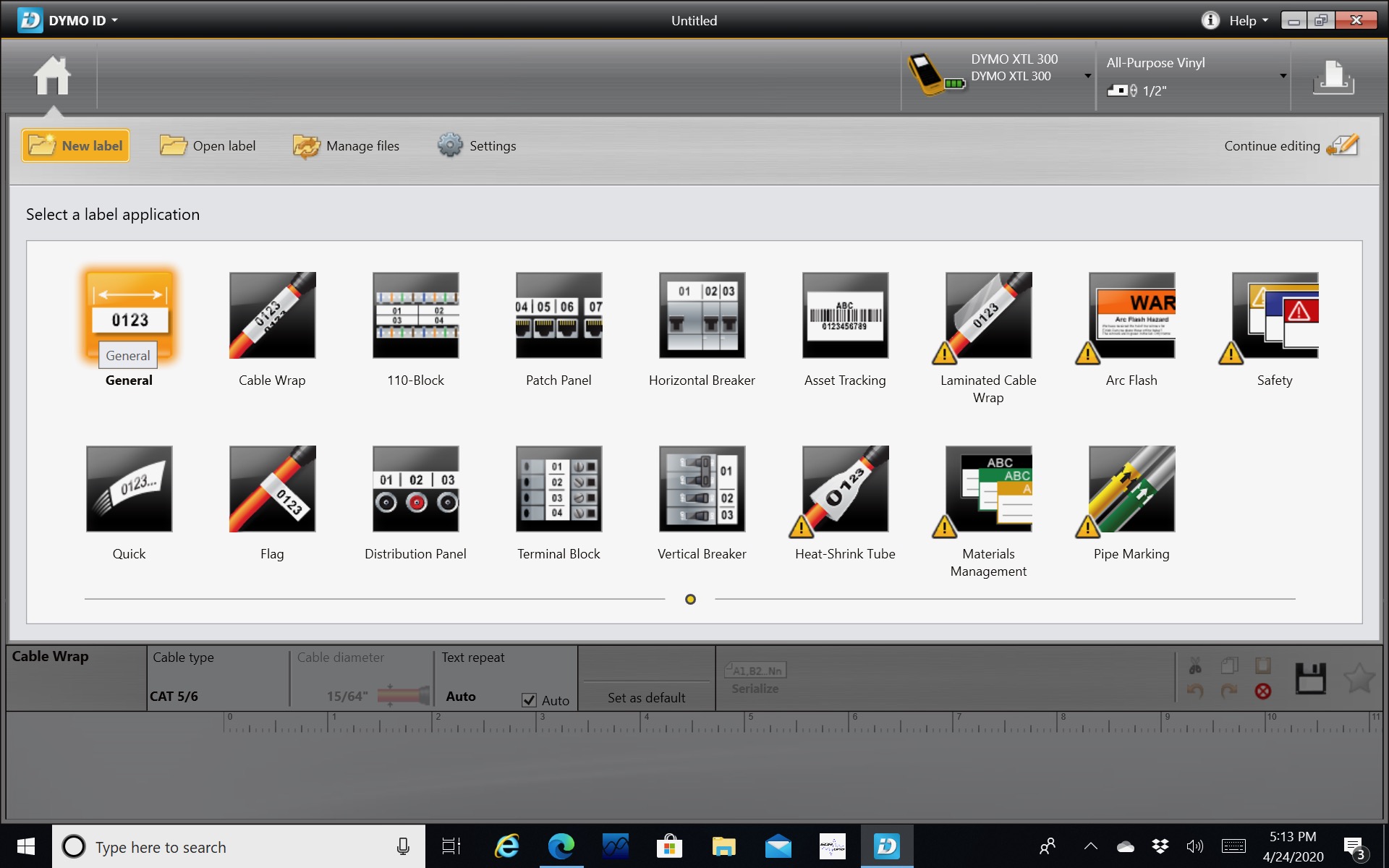

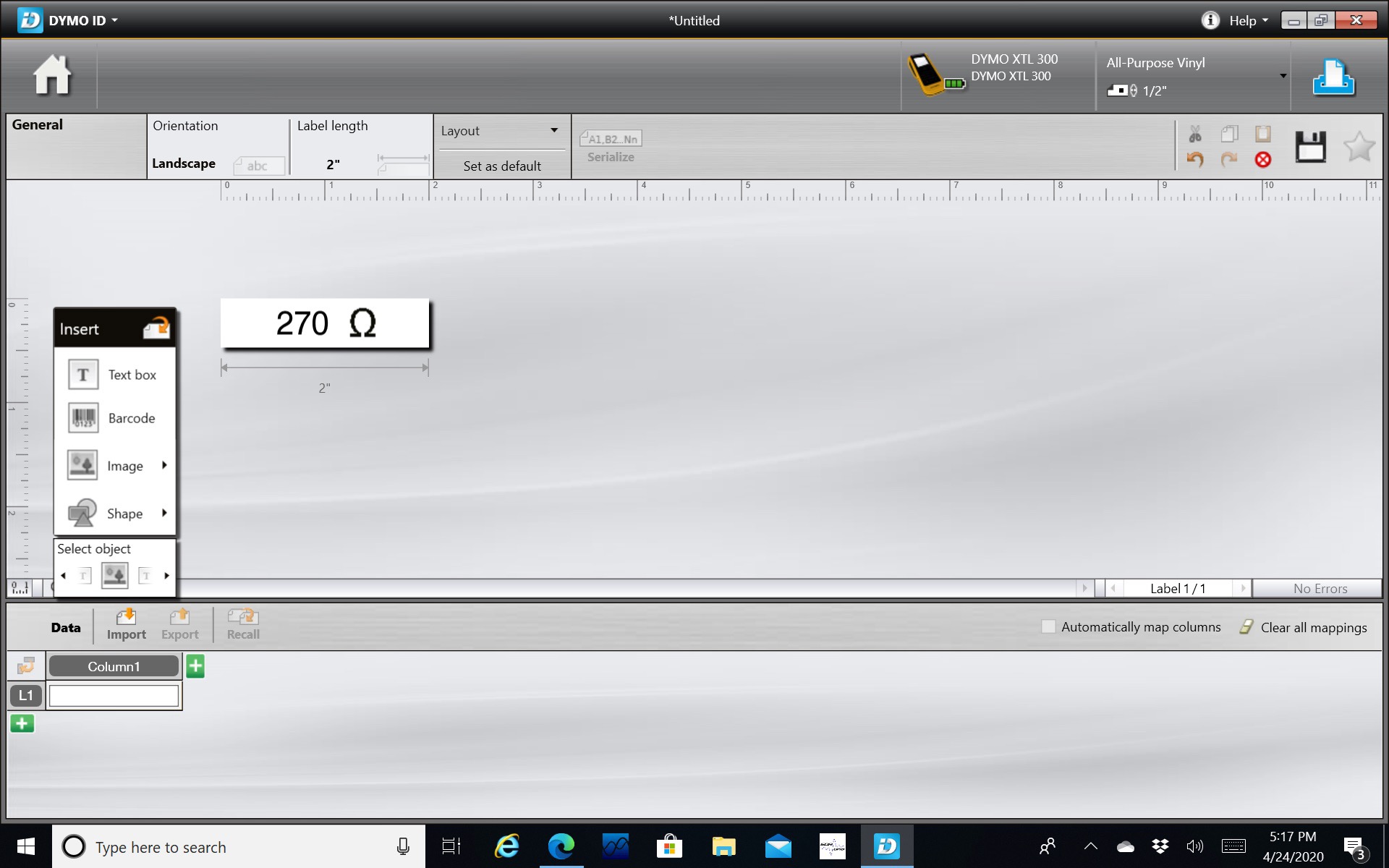

Installed the Dymo software, DymoID on a Windows only computer. Sucks that there is no Mac software but I do keep a windows tablet and laptop around for just such emergencies. Surprisingly the software looks a lot like the display looks when in hand held mode.

DymoID Software for XTL

It does a nice cadre of symbols and electrical symbols which are important for me in some work applications.

DymoID symbols

I’ll deep dive the XTL 300 as I get some good usage out of it. The one thing that scares me though is future cartridge availability. There is only the XTL 300 and XTL 500 and they are both a few years old. This fear may be unfounded but it’s still my fear.