Here is a common occurrence on laser forums and groups. Post a picture of something cool and within about 4.1643 seconds someone will ask, “What Are Your Settings?”

Unquestionably a valid thought from someone who saw what you did and seeks to emulate it. And most of us want to help answer that question. We really do.

But there are a LOT of variables involved in a burn. My settings could produce great results but could start a fire at your house. Here’s an example worth noting that happened to me just today. I have a K40 laser and have settings saved for Baltic Birch Plywood. I bought a new lens and cleaned all the mirrors and ran a job. That which was supposed to etch my plywood burned slap through it. New lens was a heck of an improvement, I guess.

Here are some variables:

- The type of wood or material you are burning on. I may have 3 layer Baltic Birch and you may have 7 layer. My plywood may have glue made by virgins with harps and your glue may have been produced by the Communist Chinese.

- The direction of the grain. Lasers etch and burn better in some directions than others.

- Air Assist. If I have an air assist and you don’t then my settings may not be relevant to your setup.

- Focus. I may be focused using a microscope and you may have no idea of what the actual state of your focus is.

- Temperature. If using a CO2 laser, cooler water temps can produce more efficient burns.

- Lens cleanliness. If my lens is clean and yours is dirty my settings are useless to you.

- Diode intensity. I may have a brand new diode laser and you may have been burning at 100% power for 6 months. Diode lasers wear out. CO2 in a laser tube depletes. Also you might have a 4.5 watt output and I might have a 5.5 watt output laser.

I’m probably missing a couple of things here but I think you get my point. Before burning you should perform cleaning and maintenance on your machine. Use quality materials that you know others use successfully. And if you buy sheets of something………..buy an extra sheet TO PRACTICE ON. If you are doing a rotary on a stainless steel, powder coated cup ……..buy one extra and burn on every square inch of that thing that you can. Practice with different speeds and intensities.

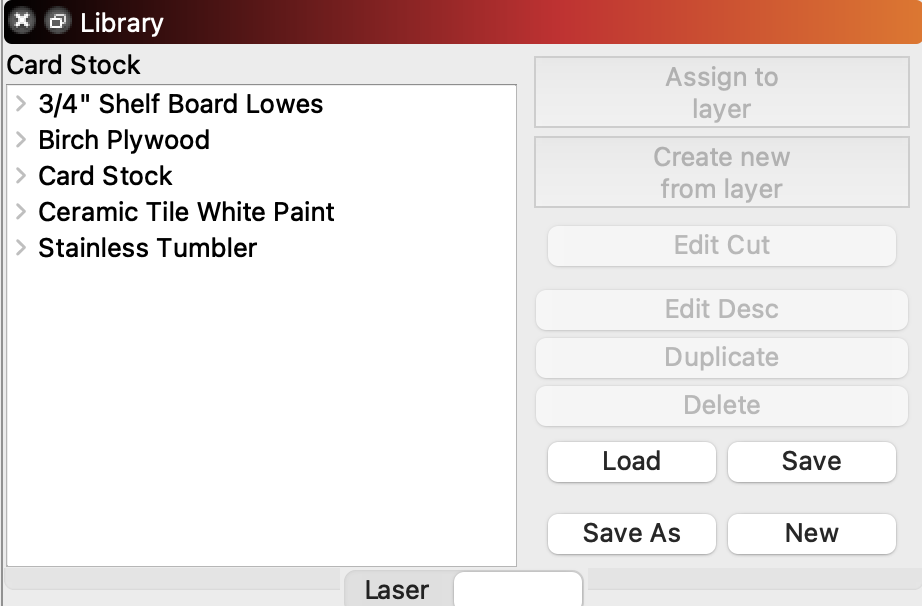

Software like Lightburn allows you to maintain a Library of materials and settings. USE IT! hit that “Assign to Layer” button when relevant.

LightBurn Materials Library

Certainly getting a starting point from advanced users is helpful but it is not the end all, be all that you might hope that it is.

And I would strongly caution against getting someone’s settings and using it on that only piece of material you have that you think you are going to sell to someone.

The old adage, “Practice Makes Perfect” comes into play here. In the mean time, if you ask me my settings, I will happily tell you and I genuinely hope it helps you……….but it is no guarantee that one of the many variables might reach out and get you.