Algolaser Alpha Review

Sign

Introducing the new Algolaser Alpha.$799. John’s Tech Blog was provided with what appears to be a 1st batch production machine for review by the folks at Algolaser. No pressure was applied for a positive review. The provided link above is an affiliate link which helps support my page.

SPOILER ALERT: This is a cool machine!

Desktop diode lasers have been available commercially since about 2019. At that time desktop lasers were typically low powered devices and their mainboards were only smart enough to control movement along an X and Y axis.

A lot has changed since then with the advent of 32 bit motherboards capable of precision movements. The Algolaser Alpha provides advanced electronics to include gyroscopes and heat/flame detection. Additionally, there is laser over exposure protection which stops the machine if flame if probable. User safety and precision seem to be paramount with the release of the Algolaser Alpha. Also, these much more powerful motherboards contain Internet of Things chips (IoT) which have ESP32 S2 chipsets which allow for multiple connection methods such as USB, Bluetooth, and WiFi.

Deeper Dive

Since I had not previously heard of Algolaser or the Alpha laser prior to them contacting me, I set my research wheels in motion prior to arrival of the machine. The company is founded by Mr. Justin Tan. Anyone who has been following the historical development of consumer laser engravers knows who this is. This is an exciting development as far as I am concerned.

The company is so new that the Alpha appears to be pre-release at the moment and a Thank You card in the box states that the machine I received is a first batch production run.

Machine Description

Typically i don’t like to list any stats when I’m doing a review nor will I do an Open Box discussion. Anyone can go to a vendor website and see “What’s In The Box” or a list of specifications. Listing it in a review is redundant information in my opinion. In this particular case where the machine appears to be pre-release I think it is important to prospective purchasers to have a bit more information. So, I’ll break my own rules just a bit in the subsections below.

Frame Construction

Frame construction and rigidity is so important to repeatable accuracy in desktop laser engravers. Tight, and precise fitting corners combined with strong materials provide the basis for success or failure of a machine. The Alpha is built with 6063-T5 Aircraft Aluminum. Its construction is low and extremely stable. Precise fit seems evident in the corners.

Frame Fit

I found the stability was good even prior to the installation of attaching hardware (3 screws in each corner).

Plastic coatings and red covers are attractive and the large round feet on each corner give it some grip and added stability.

While it does sit low, the round rubber feet will easily allow for solutions to lift the machine to allow for material pass through if required. Quality control is so important in frame construction and there are some laser companies out there with horrific quality control. Algolaser is NOT one of these companies. Fit, finish, and hole alignment were exceptional.

Laser Head

The included laser head is an impressive 20 watts. The laser wavelength is 455 nm plus/minus 5nm. This is standard for desktop diode lasers. Most diode modules are along the lines of 5.5 watts and combining several into one beam are what produce power increases. Pretty safe to say that there are 4 diode modules here and the output power is probably more along the lines of 22 watts.

Laser Head

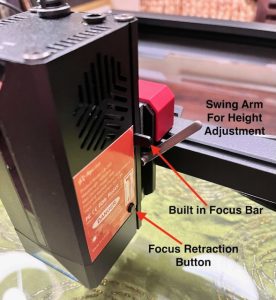

We have some interesting items built into the laser head. There is a swing arm for height adjustment. Pulling the lever down allows you to position the height and stowing the arm in the up position locks it into place.

This is a nice inclusion as most laser have a thumbscrew which is awkward.

There is a focus mechanism which is built into the module. This allows for a fixed focal distance of 55mm.

Pulling the bar down deploys the focus bar and pushing the retraction button pulls it back up. Having built in focusing mechanisms is a gigantic plus. Gone are the days of the focusing block which was easy to misplace or lose altogether.

Laser Spot Size

The laser spot shape is rectangular and is advertised as being 0.16mm along the X axis and 0.14mm along the Y axis at 100% power. This is typical and the rectangular shape comes from the combination of the 4 laser diode modules. At 30% power the spot size is 0.08 x 0.07 mm which is pretty impressive.

Ultimately, the smaller the laser spot, the greater the precision in engraving detail.

Optics

Optical pathways are quartz glass and there is a replaceable glass cover which protects the actual lens assembly. So many laser companies do not provide this and in my opinion it is a MUST. Nice to see the inclusion of a replaceable lens protector.

Air Assist

Air Assist Pump In The Kit

The kit comes with a built in air assist. All lasers should come with an air assist. But they don’t. This is huge! The pump air volume is adjustable as well. Bonus points here!

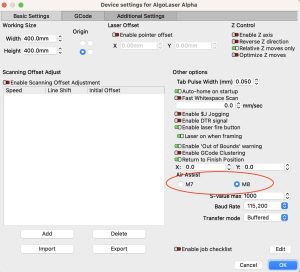

The air pump is controlled via software in Lightburn or LaserGRBL by ensuring that Air Assist is set to M8 in the Device Settings. Below are the instructions for doing it in Lightburn.

M8

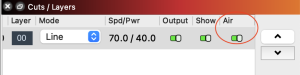

Then you can use, or not use, the air assist simply by toggling it on or off in the individual layers.

Air Assist Setting

Additional Specifications

For a list of all specifications go here.

Assembly

Subsequently, I was going to create a subsection above called “Wire Management” but decided to include it here. There is a bit of difference between the Algolaser Alpha Quick Start Guide assembly procedures and how the machine parts actually were assembled in the box.

The instructions show that you take the 4 frame pieces and screw them together in the corners. The reality is that the wire management is pre-installed on the left side of the frame and the X rail to include the laser head itself. All three of these components are tethered and must be handled together.

Wire Management

Believe me, I am not complaining here. Other than differing from the assembly manual a bit this saves the assembler a ton of time and takes care of all the tedious work. On the left side rail (Y) the wires and hoses run along the bottom of the frame which is brilliant. Out of sight, out of mind.

The only other thing I’ll say about the pre-installation of the wires and air tubing is that the builder should just take care and work slowly and methodically when assembling. You need to turn the machine over a time or two and all those tethered components need to be handled carefully and gently. But in the end you’ll be glad they did these steps for you. I was.

I didn’t put a clock on my assembly time but after you screw the frame corners together and plug JST and laser connectors in where instructed ……… THAT IS BASICALLY IT. Lastly, you just need to tension the 3 belts (2 Y, 1 X) which I found to be super easy.

Software and Testing

I’m going to throw you a bone here. After I built the machine I went into Lightburn to add it as a device. Conversely, I didn’t see the bed size listed in the manual but it is on the specification page I linked to earlier. Your Lightburn device parameters are:

- GRBL

- Serial / USB (you can do wifi later)

- Name the Machine (Algolaser Alpha)

- Bed size is 400mm X by 400 mm Y

- Origin = Front Left

- Auto Home at Startup = on

Does It Work?

You bet it does. As soon as I turned the machine on it auto homed and my first burn was the word “test”. It worked perfectly. Every time I build a machine I video the first test and publish it, good or bad. Unfortunately, on the actual first run I took a photo instead of a video. So this is actually the 2nd test. Both runs went identical and successful.

[kad_youtube url=”https://youtu.be/UaRk79YYd5Y” ]

Additional Testing

One of the most important requirements for a desktop laser is something called Repositional Accuracy. That is where you burn or cut one pass and the laser returns to its origin point or home. Any subsequent 2nd or additional passes should be PERFECT with no signs of fuzziness or doubling. Most lasers with 32 bit motherboards and good belt tensioning are good at this. However, surprisingly, some are not.

Stepper Drivers are vital here and the Algolaser Alpha uses HR4988 drivers. These have a solid reputation in the world of 3D printers and lasers. They are designed to operate bipolar stepper motors in full,1/2, 1/4, 1/8, 1/16 step modes. This should give us excellent results.

The Algolaser Alpha shines in repositional testing as shown in the video below.

[kad_youtube url=”https://youtu.be/HA56jhWendI” ]

Scattering various shapes around a large area and having the machine home before initiating a 2nd pass is a worst case scenario for checking laser pass accuracy. You can be assured that this machine has excellent accuracy.

Cutting And Engraving

I typically don’t do cutting tests as there are so many variations in wood types and wood grain that taking a lightweight wood and demonstrating how thick it will cut just isn’t a real world indicator of cutting ability to me. I seldom do any serious cutting of materials and stick mostly to engraving. There is no doubt in my mind that this 22 watt laser will cut within reason.

Real World Examples

Needed a sign for my back yard gate so I decided to let the Algolaser Alpha tackle that task. It did not disappoint.

[kad_youtube url=”https://youtu.be/I0qTadHeB8U” ]

Pic

Sign

Firmware Version

Firmware reports ALF107 dated 3 July 2023

[ORIGIN:China] [PRODUCER:Algolaser.com] [AUTHOR:Algolaser.com] [MODEL:AlgoLaser Alpha] [ALF:107] [ALH:AlgoLaser AM V1.2] [ALM:GENERAL] [DATE:20230703] [SN:9CBD0891150B1A2AD26DC60F6910CB86] [VER:1.1f.20220325:] [OPT:VNZHS,63,32767,3,0] Target buffer size found [NEWOPT:ENUMS,RT+,HOME,NOPROBE,TC,SED,CLU,WIFI,FTP,SD,ITG,GT,YRR] [FIRMWARE:grblHAL] [NVS STORAGE:*FLASH] [DRIVER:ESP32-S3] [DRIVER VERSION:220327] [DRIVER OPTIONS:v4.4.3-dirty] [BOARD:AlgoLaser AM V1.2] [TYPE:ALA1] [CLUSTER:16] Cluster size found [WIFI MAC:34:85:18:A7:CC:CC] [IP:192.168.5.1] [PLUGIN:Power Detecter v1.0] [PLUGIN:Power Control v1.0] [PLUGIN:Gyroscope Sensor v1.0] [PLUGIN:SDCARD v1.05] [PLUGIN:ITG STREAM v1.00] [PLUGIN:GADGET v1.00] [PLUGIN:YRR v1.00] ok Homing <Home|MPos:0.000,0.000,0.000|Bf:63,32767|FS:0,0|CL:0|PS:2,0|Ov:100,100,100|A:FM|H:1,7> <Home|MPos:0.000,0.000,0.000|Bf:63,32767|FS:7071,0|CL:0|PS:2,0|A:FM> ok

Pretty sure that is latest.

GRBL Defaults

Here are the results of a $$ command in the console

$$ $0=5.0 $1=100 $2=0 $3=0 $4=7 $5=3 $7=0 $10=2047 $11=0.050 $12=0.002 $13=0 $14=0 $15=3 $16=0 $17=4 $18=0 $20=1 $21=1 $22=1 $23=7 $24=1000.0 $25=5000.0 $26=150 $27=3.000 $28=0.100 $29=0.0 $30=1000.000 $31=0.000 $32=1 $33=2000.0 $34=0.0 $35=0.0 $36=100.0 $37=0 $39=1 $40=1 $43=1 $44=3 $45=0 $46=0 $62=0 $63=3 $64=0 $70=27 $73=1 $74=My_SSID $75=*********** $76=ALA1_AP_CCCC $77=12345678 $100=100.000 $101=100.000 $102=100.000 $110=30060.000 $111=30060.000 $112=600.000 $120=2000.000 $121=1800.000 $122=200.000 $130=400.000 $131=400.000 $132=100.000 $160=0.000 $161=0.000 $162=0.000 $180=30060.000 $181=21042.000 $182=600.000 $270=115200 $271=115200 $272=115200 $300=ALA1_STA_CCCC $301=1 $302=192.168.5.1 $303=192.168.5.1 $304=255.255.255.0 $305=23 $307=81 $308=21 $310=ALPHA_AP_CCCC $312=192.168.5.1 $313=192.168.5.1 $314=255.255.255.0 $332=255 $341=0 $342=30.0 $343=30.0 $344=180.0 $345=200.0 $384=0 $600=0 $601=5 $602=0 $603=5.0 $604=6.0 $605=1 $606=1 $607=0 $608=1 $609=10.000 $610=0 $611=0 $612=1 $613=4294967295 $614=0 $615=firmware.algolaser.com $616=0 $617=0 $622=111

Everything looks fairly standard to me.

Comments

One minor oddity When mine is on and idle the laser head makes a weird repeating noise. It’s not very loud, and everything works perfectly but I’m just not sure what the noise is.

[kad_youtube url=”https://www.youtube.com/watch?v=nSUoNClj7pE” ]

I’ll reach out to Algolaser and see if this is normal.

Additional Information

This is just my initial review. I’ll follow this up with another entry or append this one in the very near future. I’ll play around with WiFi and bluetooth and report on that later. I typically don’t use WiFi on lasers especially if bluetooth is available.

The Algolaser web page leaves a bit to be desired at this moment but again, I believe they are in a pre-release status and I’d be willing to bet lunch the page will improve on release day.

Initial Review Thoughts

THIS IS A GREAT DESKTOP DIODE LASER! There. I said it. The motherboard is well equipped with many safety features and includes a giant Emergency Stop button. Movements are precise and repeatable. The Air Assist is software controlled and volumetric output is adjustable to suit your engraving needs.

The frame is rigid, stable, and attractive. The laser head is powerful and has a small laser spot. Focusing and Z height adjustments are built into the laser head and cannot be lost or misplaced. I especially like the swing arm and the fact there aren’t thumbscrews to loosen and tighten to adjust Z height.

I have not seen reliable pricing data yet and the 2 or 3 prices I have seen from Gearbest and Aliexpress don’t seem to match up. It is recommended to wait for the release price on the official Algolaser website. Even with the pricing I have observed I will state it is about the norm for a machine of this output wattage and size especially since it includes an air assist.

Anyway, I don’t think it is possible to go wrong here with the Algolaser Alpha.

John’s Tech Blog highly recommends the Algolaser Alpha.

Pingback: Algolaser, A Deeper Dive - THE LASER OG BLOG

Pingback: Algolaser Alpha MK2 Laser Engraver Review - John's Tech Blog

Pingback: Algolaser Alpha MK2 Laser Engraver Review - THE LASER OG BLOG

Save your money do not buy from them their customer service is a joke.

I started to not approve this post but I kinda beg to differ. Algolaser split off from Ortur. The Service guy, Gil was at Ortur and he was awesome. Gil went over to Algolaser with the owner. I had all manner of problems with my Ortur LM3 and LM3 LE and Gil always worked with me and help solve the issues. Conversely, people are complaining like crazy about Ortur customer service. I’m pretty much done with Ortur and have had good experiences with Algolaser so far.