LASER ENGRAVING SIDE HUSTLE SKILLS

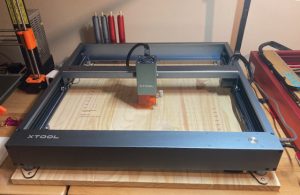

INTRODUCTION

It seems like everyone is doing a side hustle from home. With the advent of reasonably priced craft machines such as Cricut, CNC routers, and laser engravers, everyone is jumping into the game. This is a reasonably new phenomenon as well as desktop laser engraving machines have only been around a couple of years. There is one notable exception. The Chinese K40, CO2 laser.

OMTech K40

I personally think every laser side hustle wannabe should be forced to own one of these first.

Modern, refined laser engravers do much of the heavy lifting for you these days. The K40 made you learn every single skill the hard way. It required a lot of tedious setup, and utilized a rag tag method of water cooling.

Early users had to draw their designs in Inkscape and the color of the line determined whether the software (K40 Whisperer) either engraved it, or cut it out. Additionally, just getting that machine set up, and aligned taught the user vital skills. The K40 forced you to learn the difference between vector and raster drawings. Having dirty lenses and mirrors were anathema to engraving success. DIY upgrades were often vital to keeping the machine operating within recommended parameters. Jumpers were installed on the main board which defeated safety measures such as detection of water flow. Wow! I’ve blogged about much of this in the past.