Disclaimer: I’m by no means an expert. Yet. And your mileage may vary. These are my considerations.

UPDATE: I had to update this post as I had previously selected and ordered a Shapeoko 4. Their lead time indicated shipping in 5-6 days. After 10 days of hearing nothing I cancelled my order after hearing on a forum that others who ordered days before me were told (after they had trouble getting an answer out of anyone) that their units MIGHT ship in a week or two. John don’t play that shit. It’s one thing to have a shipping delay but it is an entirely different thing to have a delay and not inform someone who has dropped a couple of thousand dollars that there has been a delay. I simply CANNOT recommend to anyone to buy the Shapeoko machines. What if there is a problem? If they can’t deliver on the front end, they might not be able to deliver on the back end.

Well I bought a Sainsmart 3018 Prover CNC and while it is super cool about the first thing it revealed to me was that I was going to outgrow this thing FAST. I want to make big signs and in some respect I can do that now with simple wood working tools and my CO2 laser.

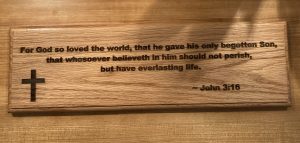

Larger Sign

This is John 3:16 on about a 19″ piece of cedar.

Simple routed edge, then lasered, then wiped down with Butcher Block oil.

Looks magnificent. No complaints at all.

But I can CARVE exquisite details with a CNC. But how to choose which one? Let me tell you my choice and how I arrived at it.

First off, there is no shortage of CNC machines out there and I won’t even begin to list them. One of my largest selection criteria is SPACE. I don’t have a lot of it. CNC’s make huge messes, unless you have a filtered collection bin, that means the machine is living in your Garage or Shed. I have a one car garage but I do have a man shed in the back yard. The man shed has a work bench that will accommodate a 24″ router. Adding a 4′ table in this shed is out of the question. There just isn’t real estate for it.

So here are my considerations:

- Space – Just mentioned that and it is on the top of the list.

- Software – I find it appalling that some $2000 machines come with subscription software.

- Software business model – I want the software. I do NOT want web based software.

- Security – I’m currently cutting my teeth on Easel which is web based (yeah, I know I just said I hate that). My machine WILL NOT CUT if I use a local machine for a DNS server. I have to use my ISP’s DNS server addresses or Cloudflare or OpenDNS or GoogleDNS, etc. This pisses me off. I spent a lot of time and money on a hardware firewall and configuring everything for DNS to have one machine that won’t play along. Also Easel Pro is $450 FOR 3 YEARS ONLY. So right away this leaves the Inventables X-Carve machine out. And yes, I know I can use other software with it. I just don’t appreciate that business model.

- Cost – Of course cost is a consideration. A new friend of mine has a Next Wave Shark CNC that is freaking amazing. But it is twice as much as most CNC’s. It is probably worth it though. I would tend to call it an Industrial CNC more so than a hobbyist CNC. It is impressive.

- Support – Some machines seem to have more support issues than others.

- Warranty – Some machines have little to no warranty.

While there are again several manufacturers and models to choose from, I narrowed the field quickly to

- Bob’s CNC

- Inventables X-Carve

- Carbide 3D Shapeoko 4

- Maslow

- LongMill CNC

- NextWave CNC

After reading forums, watching videos, looking at support issues and just doing all the research in general I could I narrowed it down further to:

- Inventables X-Carve

- Carbide 3D Shapeoko 4

- NextWave Shark HD Series

Inventables has that Easel software I talked about earlier that is web based that is a subscription model that pisses me off. At some point I will likely buy VCarve Pro software which negates the subscription software issue. But for now I’m not getting it until I learn the basics of the new machine.

Also lets say you have web based software and your internet chokes. Gee that never happens, does it Suddenlink? Your job will just fail. Imagine doing a 2 or more hour longer cut on expensive wood and it fails. Of course your power could go out but if it were super super critical to me and like Tennessee Tuxedo, “I will not fail”…….(you probably gotta be my age at least to get that reference)……..I’ll hook my stuff up to a generator.

Carbide 3D Shapeoko 4 comes with Carbide Create stand alone software which I am actually using now and I send my Gcode into Easel. There are other ways to get Gcode to the machine but I do find Easel to be EASY, especially since I am just starting out. They also have Carbide Motion which controls the machine and cut. Carbide Create only does 2D and to do 3D stuff you need Carbide Create Pro. Here we go………$360 gets you the forever software but if they update after a year and you WANT the update you have to pay $120 for it.

This really makes VCarve Pro more attractive all the time. Yeah it is $700 but it is “One and Done”. If I’m going to drop $360 with the expectation that I’ll have to upgrade if I dare upgrade my OS or something I’ll just get VCarve Pro.

Here’s the downside to VCarve Pro. WINDOWS ONLY. I hate Windows. The Carbide 3D software works on a Mac which is my platform of choice. So at least I HAVE A CHOICE HERE.

The Shapeoko seems to have product maturation, a great support community, and great after sales support from the manufacturer.

The one complaint I keep reading about the Shapeoko is that I don’t think anyone has ever gotten a CNC from them without some missing parts. I know that is an exaggeration but it’s prevalent on the user forums. It is a problem. Everyone though that complains does say that they will overnight ship whatever is missing. So I guess you roll the dice with the Shapeoko order. As I mentioned at the top of the page they don’t communicate at all.

In the end I went with the Shapeoko 4 and then cancelled that order and bought a NextWave Shark HD500. The Shark HD500 has a slightly smaller working area than the Shapeoko XL however it has a much higher Z axis capability. 7 inches compared to 4 with the Shapeoko.

Also the Shark has Lead Screws and NOT belts and is much beefier. Unfortunately so is the price tag much beefier. One great thing though is that the machine comes with Vectric VCarve Desktop. Software for these things isn’t cheap and VCarve Desktop is great software to get started with. By the time I bought the Shapeoko and Vectric software my cost would have been roughly the same.

After just a few days the NextWave Shark has already shipped. Assembly is much easier as well.

Again, your mileage may vary, and it may vary a lot. I’ll expand on this when I actually get my machine and report back whether or not I think I made the right choice.