Epson LW-PX700 Label Maker Review

Epson LW-PX700

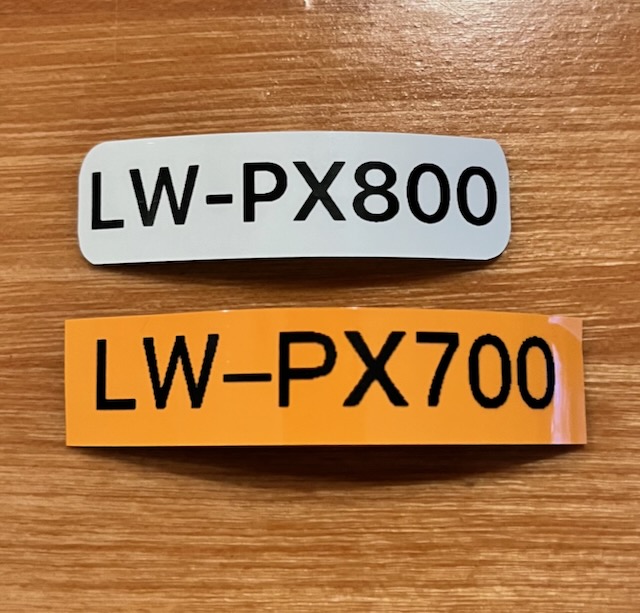

It is no secret that I love label makers. I have picked up yet another one in my quest to test them all. Today I will be testing the Epson Labelworks LW-PX700 ($129). Epson had a 15% off campaign and that’s when I jumped at the chance to get one.

Best of all after ordering mine directly from Epson I got an email stating that VIP members could get a Buy One, Get One label maker. I immediately emailed Epson who altered my order to BOGO. I lost the 15% discount but got TWO LW-PX700’s for the price of one. WOW!

It can also be purchased in the Deluxe Kit also known as the LW-PX700PCD ($209). I ALWAYS recommend getting the deluxe kits as they include a lithium ion battery, an AC adapter, a USB cable, magnetic mounting feet, and a roll of tape to get you started. Top that off with a hard carry case and you are all set.

Included with just the label maker is an AC adapter and 1 tape cartridge. No battery.

However, this time I did not get the Deluxe Kit. I already own the Epson LW-PX900PCD Deluxe Kit. All the accessories are the same. Most of the extra cost is wrapped up in the lithium ion battery ($79) which is NOT included when you buy just the LW-PX700.

Redundancy In My Case (pun intended)

So, I already have a PCD kit. Also while price shopping for a used one on eBay I found a lithium ion battery for the 700/900 for $20. It has a pretty recent manufacture date on it, and the seller has a good reputation so I decided to take a leap of faith on that one. About the only thing I’m short on here is the hard case. Essentially, in my situation, buying the PCD kit would have been redundant.

You probably think I’m crazy to buy a LW-PX700, much less two, when I already own the LW-PX900. You’re right. I’m crazy. Let’s move on. Seriously, I have no need to own both, but I love to review tech gear. It’s what I do in retirement.

Epson LW-PX700 Leading Particulars

The LW-PX700 is a slightly less capable label maker than the LW-PX900. These are the KEY differences.

| FEATURE | LW-PX700 | LW-PX900 |

| Print Resolution | 180 dpi | 360 dpi |

| Maximum Label Size | 1″ | 1 1/2″ |

| Cost | $129 | $319 |

Essentially, the 700 is pared down a bit for users that don’t need every bell and every whistle. Right after that the 700 has almost all of the same capabilities. Every label cartridge can be used as with the 900, with the exception of tapes over 1″ in width.

Users can label with a variety of colors and materials to include fluorescent, die cut, heat shrink tubing, magnetic tape, and ribbon. Additionally, Epson now has I think, over 130 different cartridge options. That is far and above more choices than any other label maker manufacturer. Not only can you label the warehouse shelves you can create a myriad of fun projects and get organized to boot.

Resolution

I have a lot to say about label makers and print resolution. A lot of people instantly scoff at a label maker with 180 dpi resolution. While it is true that you can look at a label printed in 180 dpi and see some artifacts from the blocks in photographs or under magnification…….who does that? If you put a label on something and look at it from a normal viewing distance, 180 dpi looks crisp and clear. No one, and I mean no one, is going to have anything to say about the appearance of that label.

Resolution numbers are for people who count pixels. You really only need higher resolution when you get into gigantic labels such as in pipe marking or safety stickers.

Otherwise, know this. More dots per inch means more cost. Speed, and heat of the thermal print head plays into this as well. More heat and faster speed during the thermal transfer process equates to reduced battery life as well.

The larger the label, the more apparent the pixelation. That’s why label makers with 180 dpi typically aren’t going to have gigantic print sizes. Anything over 1″ in width is going to probably need a bump in resolution.

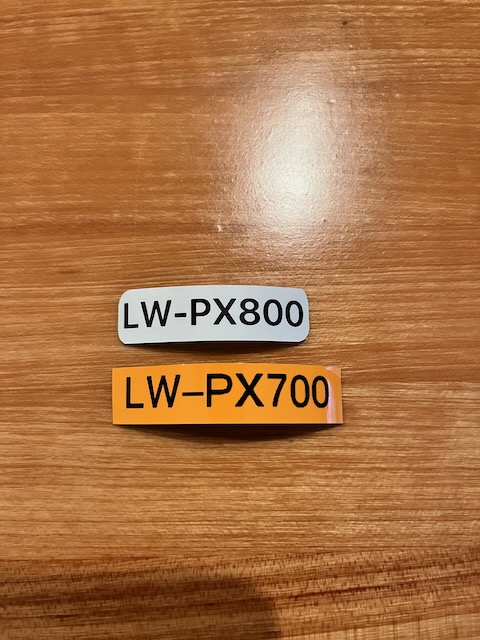

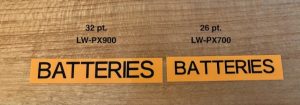

If you are just making labels for general organization or for crafting, or gifting know that 180 dpi is going to be way more than adequate though. Here is a comparison between 360 dpi and 180 dpi. The label LW-PX800 was printed at 360 dpi on the PX800 label maker. Conversely, the label LW-PX700 was printed at 180 dpi. From a normal viewing distance they both look almost identical in legibility. It is only when you zoom in on them that you see a difference in pixelation.

Resolution Differences (click pics to enlarge)

You have to ask yourself if that resolution bump is worth a considerable amount of expense when NO ONE is going to view your label at anything other than normal viewing distance.

Font Size

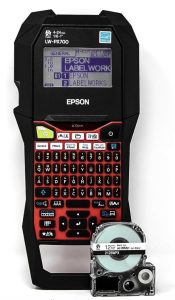

I kind of found this by accident. I printed labels for my stackable bins with my Epson LW-PX900. The labels are 1/2″ wide and had 32 pt font (Sans Serif). 32 pt. seems to be the max size obtainable for 1/2″ general labels on the LW-PX900. Anyway, they all looked the same.

When I printed a similar label the largest font I could squeeze out of the LW-PX700 was 26 pt. It didn’t look the same.

After asking Epson Support they quickly responded that this was an upgrade in the firmware for the LW-PX900 which allowed the larger point size and it had something to do with lower hanging characters such as j and g.. Since there has been no firmware update for the LW-PX700 the lower font size calculation persists. I’m not sure if the LW-PX700 can even be firmware updated currently.

Differences in Font Sizes

All I can say is that if this somehow matters to you, then level up, bro. Get the LW-PX900.

Features

One of the coolest tricks that Epson does is to include a Half Cut feature in most of the PX line of label makers. Half Cut means that only the label material is cut and not the backing material. In essence, you can cut a bunch of labels in one strip and peel them off one at a time. If you do a bunch of sequential labels and cut them one at a time they’ll get mixed up. The user then wastes a bunch of time finding #2, then #3, etc. in the pile of labels.

Half Cut Feature

The 700 does all the fancy tricks such as bar codes, QR codes, and sequential labeling. Another great feature is “Drop Stop”. After the label is printed it is cut automatically and then is held in the cutter so it doesn’t fall to the ground. I hate when I cut a label on other label makers and it helicopters down to earth usually behind something where it is impossible to retrieve. You can import your own images which is great if the symbols library is missing something you want to add to your label.

Connectivity

The LW-PX700 can be tethered to a computer and used with their free Epson Label Editor Software. Sadly, the software is Windows only. The software is adequate but is a little clunky at times. But, the price is right. Designing labels always seems to take a minute longer than I think it should. That being said, I seldom use the software so I never have gotten very proficient with it.

Adding your own images is a snap and I like to make magnetic strips and import QR codes with links to URL’s to my internal network devices.

Adding QR Codes To Labels

Online Training And Support

Epson LabelWorks PX has an awesome YouTube channel where they have a large library of training videos. Most of the videos feature Melissa who is the Product and Training Lead, and she calls the series “Easy Peasy Labeling”. Yeah, you’re not from Wisconsin 🙂

Seriously, no one else provides online training like this. Melissa’s videos are clear and concise and fun. The Epson videos are extremely helpful, especially as it relates to learning advanced features. It is really easy to follow along and learn, which of course is the whole point. And she tells the truth and points out the strengths and the limitations of the hardware.

Best of all, the videos are short and focus on one subject only. Most videos are 2-3 minutes in length. You are able to get the information you need fast without a lot of superfluous other info added.

I haven’t had any real support interaction with Epson LabelWorks PX personally, however, I have emailed them a few times and asked some questions. Everything is answered quickly and accurately. The reps are polite and friendly as well. In my opinion they seem to have some pride in their product and are happy to help.

Warranty

Another aspect of support is their Lifetime Warranty. They claim that if anything goes wrong, including you breaking the machine that they will replace it, no questions asked. That is unrivaled among Label Maker manufacturers. No one else does this.

Wish List

I can only think of one item that I’d want for this label maker. A firmware update to get larger fonts. If that isn’t possible due to hardware limitations (not all chips can be flashed in the field via USB) then new production units should have updated firmware.

That’s The Bottom Line Because

John’s Tech Blog Said So…………………..

If you don’t need 360 dpi and every last single trick in the book, the LW-PX700 is for you. As always, I’ll tell you if all you want to do is label “Christmas Lights” on a box in the garage this label maker is serious overkill. Conversely, if you are serious hobbyist or DIY Warrior this is the “can do everything” label maker for you. In my case, I’m always altering my network and restoring old electrical equipment. I NEED something beyond a basic label maker. I NEED heat shrink tubing. Also, I need network patch panel sequential labeling.

If you are a guy or gal who insists on owning quality tools then this label maker is a perfect choice.

Any guy or gal who is a serious hobbyist or crafter would be tickled to get one of these for a birthday or Christmas present.

It comes so close in capabilities to the best label maker in the world, the Epson Labelworks LW-PX900, and at a much lower cost. What’s not to like about that?

JOHN’S TECH BLOG HIGHLY RECOMMENDS THE EPSON LABELWORKS LW-PX700

✭✭✭✭✭ 5 Out of 5 Stars