GL.iNet Beryl AX Review

GL.iNet Beryl AX

I’ve just gotten my hands on a GL.iNet Beryl AX (GL-MT3000) travel router. Cost was approximately $100.

I’m rapidly becoming a fan of GL.iNet offerings and the Beryl AX is no exception. I also own and have blogged about the Mango V2 and the Slate Plus. I love both of them.

The major claim to fame with this router is that it does WiFi 6 and the WAN port is a whopping 2.5 GB ethernet port. That is really pushing the limits of a device that can fit in your pocket. Additionally, it barely takes up any space in a laptop bag or backpack.

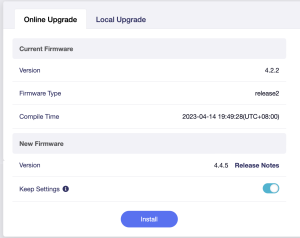

The router is based on OpenWRT 21.02 firmware. After taking mine out of the box I discovered that mine did need a firmware update from version 4.2.2 to 4.4.5. OpenWRT is an Open Source router firmware that is extremely powerful, and has greatly improved security over OEM router firmware.

Firmware Update