Updated xTool D1 Pro Review

NOTE: xTool provided me a D1 Pro + RA2 Rotary kit for review. All other accessories mentioned were purchased by me. xTool has never attempted to influence my review.

First of all let me expand on my note above. Had I not been impressed with the xTool experience I would not have purchased any accessories. So far I have bought an IR module, a Honeycomb kit , an Extension Kit with 1 additional Honeycomb panel, 8 risers, and a Laser Parts Kit. And now I’m eyeing the Air Assist kit because a friend of mine has one and it is SUPER quiet.

Also it pulls about 17 watts and the current LOUD air assist pump i use now pulls about 40 watts. If I run a job and I have any concern that a power loss would ruin the working piece……..I use a portable power supply such as a Jackery.

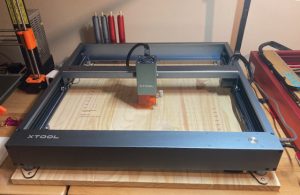

Anyway, I’ve had my machine about a month now and I have a few more things to say about it. Some may be things that I have mentioned before but have become more and more impressed with. But first here’s my setup:

Extension kit, anyone?

I added the Extension kit which makes this thing a beast with a working area of 430mm x 930mm (16.9″ x 36.6″). That’s over 3.5′ long!

I do some work with Live Edge planks of wood which are large. Typically, I make them for campers and they might have an engraving of a Compass, then the State they are from, and then the family name.

In the past I have had to treat this as 3 separate operations, moving the wooden plank and painstakingly set up each position. NO MORE! One and done, baby. So right off the bat let’s just say I love the size of the extension kit. Only one thing to note about the honeycomb panel is that it is possible when cutting to mark up your table where the two pieces butt up against one another. I may have to get some aluminum tape or something to deal with that seam. Or make a large plywood spoil board. Probably that’s the smart move.

Continue reading →